International Corrosion Services’ Expertise

International Corrosion Services are the world’s leader in the treatment of stainless steel. Operating since 2010, we have over 100 years’ worth of combined experience across our team of experts. We’re proud to offer expertise on electropolishing, descaling, pickling and passivation treatments and supplementary chemical products and services.

We work to all current and applicable standards in the treatment of stainless steel, including:

- AS 1627

- ASTM A380

- ASTM A967

- ASTM B912

We have extensive onsite services, including Western Australia’s largest Electropolish bath. Our plant also includes:

- New 5000amp state of the art German manufactured rectifier

- Mixer for agitation of the fluid

- Temperature sensor

- Electrical heaters

- Electrical control panel and control units

- Bath cover/lid (manual handling)

- Fumes exhaust system

- Waste Disposal and recycling system

- 10 tonne and 5 tonne overhead cranes

Below is a timeline of some of our major projects, showcasing our work and successes. Our wide range of treatment products and services can fit any project or need. Consult one of our specialists today to see how we can help you.

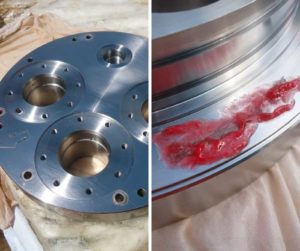

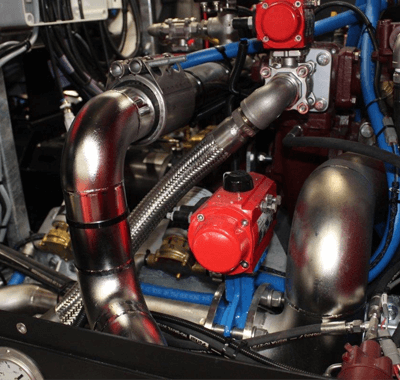

Electropolish Fire Fighting Equipment – Project Ongoing

ICS have been contracted by Frontline Fire and Rescue, who are the designers and manufacturers of Fire Appliances, Rescue Vehicles, Specialised Vehicles and purpose built trailers and equipment.

Our current, ongoing project with Frontline Fire and Rescue is to pickle and passivate stainless steel as per the following standards:

- ASTM A380

- ASTM A967

Once completed, the stainless steel is Electropolished to meet standard ASTM B912.

While most of our clients only opt to pickle and passivate their pipe stools, Frontline Fire and Rescue equipment looks fantastic polished, completing their equipment.

ICS were contracted to complete a high polish on the handrail sections on the Geraldton foreshore, 400km north of Perth.

The stainless steel was pickled and passivated to meet standards ASTM A380 and ASTM A967. Upon completion, the stainless steel was Electropolished to standard ASTM B912.

ICS were contracted by Civmec Construction to treat their stainless steel spool for their Oil & Gas Process Plant. Made via a confined space entry, the stainless steel fabrication required internal spray pickle and passivation.

The treatment of all internal stainless steel surfaces adhered to the following standards:

- ASTM A380

- ASTM A967

Offshore Angola Africa – Completed 2015

ICS were contracted for the treatment of subsea stainless steel Motion Record unit assemblies for an Floating Storage & Production Offtake (FPSO). The service vessel, based in offshore Angola, required treatment using pickling paste, cleaner, passivator and mechanical abrasion to remove corrosion on the subsea canisters.

Treatment met standards as per ASTM A967.

Kemmerton – Completed 2014

ICS were contracted by Tenix Australia to treat their stainless steel Waste Water Treatment Plant. Located in Kemmerton, W.A., the stainless steel fabrication required cleaning. The structure was fully encapsulated with scaffold and tarps.

Exchange Plaza Signage – Completed 2014

On site in Perth City, ICS were contracted by the Exchange Plaza to clean the stainless steel signage, which was both dirty and corrosion tea stained.

Cleaning of the stainless steel signage surface as per standard ASTM A967.

PTTEP Oil Rig – Completed 2014

ICS were contracted by PTTEP Australia to inspect and treat the Floating Storage & Production Offtake (FPSO), as the stainless steel was showing early signs of corrosion.

Works were undertaken offshore on the FPSO, and completed to the following standards:

- ASTM A380

- ASTM A967

CB&I Project – Completed 2012

ICS were contracted to CB&I Constructors for the treatment of a 20m diameter, 15m high stainless steel tank.

The project, including New Build Tank Internal and External Pickle and Passivation, was completed on-site and met the following standards:

- ASTM A380

- ASTM A967

TGF 999 Pty Ltd – Completed 2010

ICS were contracted by TGF 999 to treat two 10m diameter, 12m high stainless steel tanks. The work was completed on-site at the Blue Tongue Brewery in NSW, and included New Build Tank External Pickle and Passivation of stainless steel, meeting the following standards:

- ASTM A380

- ASTM A967

Consult one of our specialists today to see how we can help you.

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023