ICS offers a high-quality Electropolish treatment process in compliance with ASTM B922 standards. Our 6m bath is the largest electropolishing bath in Western Australia.

Electropolishing Services

Prevent corrosion with a precision finish that ensures optimum performance in all conditions.

What is electropolishing?

Electropolishing is the most efficient metal finishing process available. The process streamlines the microscopic surface of a metal object by removing metal from the object’s surface through an electrochemical process similar. The process is the reverse of electroplating. The metal peaks or high points of the stainless steel are shredded, resulting in a smooth finish making the finish ideal for products used in marine and arduous environments.

The ASTM standard ASTM B912 recommends pickling and passivating the stainless steel to ASTM A380, a pre-treatment process for a premium stainless steel polish result, extending the life and quality of electropolished steel electropolishing. International Corrosion Services is currently the only facility in Western Australia to be able to offer this large-scale service. Learn more

30x the corrosion resistance compared to passivation

Brighter smoother polished presentation

Superior mechanical properties

Increased corrosion resistance

Reduced tea staining, corrosion and pitting

Reduced maintenance costs

Improved physical appearance

Increased durability and longevity.

Easier to sterilise surface

Marine, Surgical and Hospitality

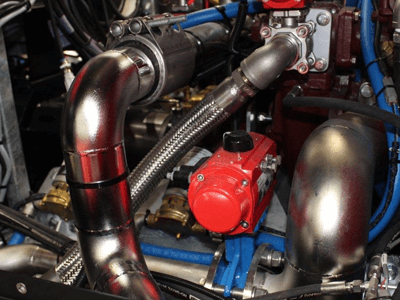

With thirty times the corrosion resistance compared to passivation, electropolishing is the ideal process for marine environments where stainless would readily rust and deteriorate. Following electropolishing treatment, parts have a smooth finish, free of burrs, corrosion resistant and clean, ideal for surgical and hospitality applications. When hydrogen is present in stainless steel it provides a suitable breeding ground for bacteria. Electropolishing is the only process that removes the presence of hydrogen from the surface and throughout stainless, protecting equipment from bacterial growth. It also removes the peaks and high points where bacteria can harbour, resisting contamination and moisture.

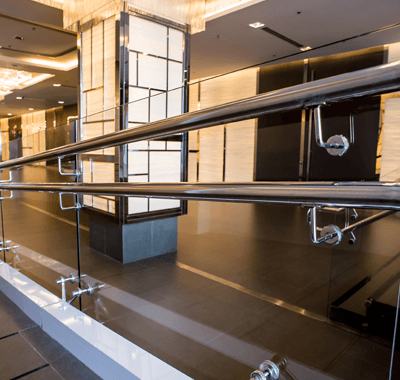

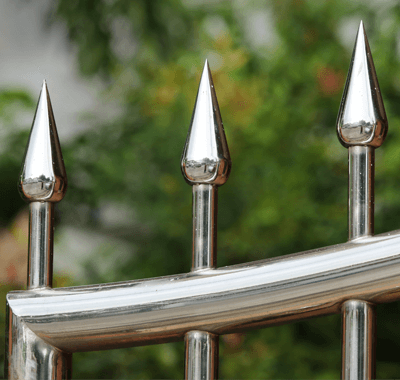

Commonly electropolished items include; Marine spools, Marine and boating accessories and parts, Balustrading and Handrails, Stanchions, Fences, Gates and Doors, Bollards, Chairs, Bins, Bike Racks, Street Art, Medical items, Fuel Tanks.

Commonly electropolished items include; Marine spools, Marine and boating accessories and parts, Balustrading and Handrails, Stanchions, Fences, Gates and Doors, Bollards, Chairs, Bins, Bike Racks, Street Art, Medical items, Fuel Tanks.

ICS Electropolishing Bath

- New 5000amp state of the art German manufactured rectifier

- Mixer for agitation of the fluid

- Temperature sensor.

- Electrical heaters.

- Electrical control panel and control units.

- Bath cover/lid (manual handling).

- Fumes exhaust system.

- Waste Disposal and recycling system.

- 10 tonne and 5 tonne overhead cranes.

Regulatory Approvals

ICS is Fully Compliant to carry out these chemical treatments

Dangerous Goods Storage Licence

Poisons Licence

Water Corporation Permit to Dispose of Industrial Waste

EPA Approval for Metal Shearing

Ongoing Emissions Assessment

SERVICE Enquiry Form

"*" indicates required fields

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023