Covalent Lithium, are constructing a world-class refinery within the industrial area of Kwinana, 35km south of Perth’s CBD.

The refinery operations are expected to recover 75% of the lithium contained in the spodumene concentrate. This high rate of recovery means the plant will be able to produce approximately 50,000 tonnes of battery-quality lithium hydroxide, per year.

This amount of lithium hydroxide will enable approximately one million electric vehicles every year to go on the road, reducing reliance on fossil fuels and helping support a greener future.

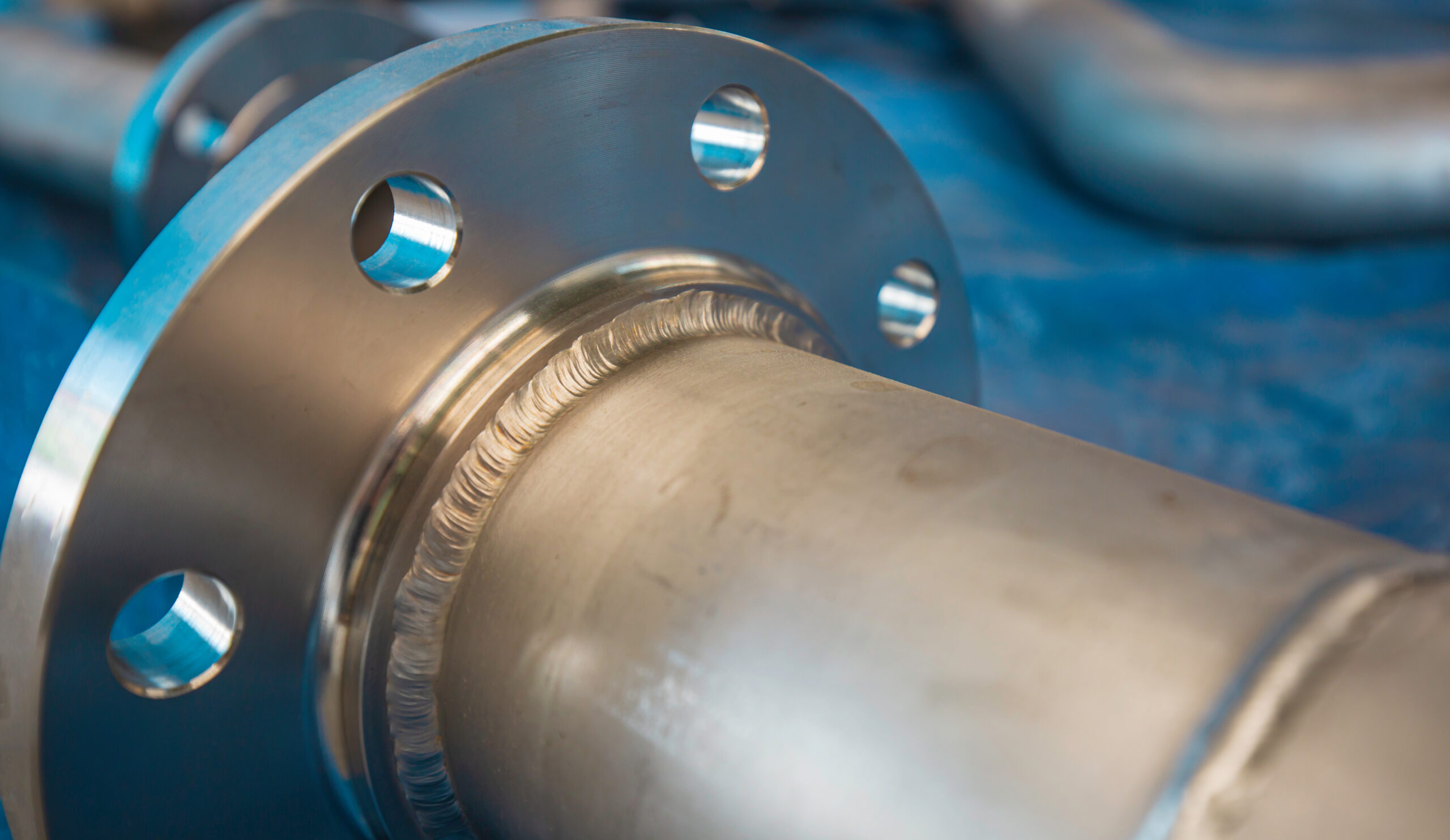

ICS International Corrosion Services are pleased to be tasked by Civmec to perform the post fabrication treatment of the stainless-steel spooling. The post fabrication treatment will be to pickle and passivate the stainless steel in compliance with ASTM A380 and A967.

ICS International Corrosion Services are pleased to be tasked by Civmec to perform the post fabrication treatment of the stainless-steel spooling. The post fabrication treatment will be to pickle and passivate the stainless steel in compliance with ASTM A380 and A967.

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023