Articles

CLIIN Robotics Wins Silver at 2024 Global Tank Storage Awards

CLIIN Robotics is pleased to announce its achievement at the 7th Global Tank Storage Awards held in Rotterdam on March 12th, 2024. The event, which brought together over 200 industry professionals, recognized outstanding contributions to safety, innovation, sustainability, and diversity in the tank storage sector. CLIIN Robotics proudly secured the Silver award in the category […]

Life cycle costing in the city of Melbourne

Published in: Australian Stainless issue #77 slot gacorslot deposit dana 5000 terpercaya WA GB Official Pro WhatsApp GB Apk Download Terbaru 2023 v9 https://tanjabbarkab.go.id/v2/wp-content/-/slot-deposit-dana/

Is there a need to Pickle and Passivate after bead blasting?

The answer to this question is that pickling in compliance with ASTM A380 is required after bead blasting to provide a passive surface. Why pickle in compliance with ASTM A380? Bead blasting with glass is generally used to match the appearance of different components such as castings or plate/sheet or pipe. The beads deform the […]

Stainless Fabrication: Common Traps to Avoid

Errors in stainless-steel fabrication can be expensive and difficult to resolve. So a ‘Get it right the first time’ approach to stainless fabrication is necessary to gain the best result. Check the ASSDA website regularly for a local Stainless Steel Specialist. ASSDA Accredited Fabricators – Ensuring the Best Result ASSDA Accredited Fabricators are companies and […]

Common misconceptions about stainless steel

Everyone knows that stainless steel resists corrosion, but beyond that, an amazing range of half-truths and exaggerations have evolved – often misleading and sometimes simply wrong. This article examines some of the more common myths, explains why they are wrong, and more to the point, provides correct information. MISCONCEPTION: There are only two types of stainless […]

ASSDA Accreditation

What does it mean to be ASSDA accredited? Accredited Fabricators belong to the ASSDA Accreditation Scheme, an ASSDA initiative that is intended to achieve self regulation of the industry, for the benefit of both industry members and end users. The Scheme gives owners and specifiers of stainless-steel greater certainty that applications using stainless-steel will be […]

Sustainability

Did you know that stainless-steel is 100% recyclable? Not only is stainless-steel durable and low maintenance, it’s also a 100% recyclable commodity. The majority of stainless-steel produced today has already repurposed. And although some stainless-steel will find its way to landfills or other disposal sites, there are no expected detrimental effects to soil or ground […]

Electropolishing – Busselton Jetty

The Busselton jetty is a shining example of our electropolishing work. Electropolishing is a process offered by International Corrosion Services that streamlines the microscopic surface of a metal object. Metal is removed from the object’s surface through a process that is similar, but the the reverse, of electroplating. Metal peaks and high points of the […]

The Safety and Environmental Impact of Stainless Steel Treatments Explained

At International Corrosion Services we take our commitment to the safety of our staff and community and preserving the environment and reducing our emissions footprint very seriously. It’s not easy working with the dangerous chemicals that are needed for the treatment of stainless steel and we take every precaution we can that we work within […]

Onsite Stainless Steel Cleaning That Won’t Take You To The Cleaners

The pre-commissioning stage shouldn’t be the only time your stainless steel system or installation sees a good cleaning, pickling, and/or passivation, although it may be the most important time. Doing this periodically after it’s been put to work and removing process contaminants, will help to maintain the life and integrity of the stainless steel. It […]

International Corrosion Services’ Expertise

International Corrosion Services are the world’s leader in the treatment of stainless steel. Operating since 2010, we have over 100 years’ worth of combined experience across our team of experts. We’re proud to offer expertise on electropolishing, descaling, pickling and passivation treatments and supplementary chemical products and services. We work to all current and applicable […]

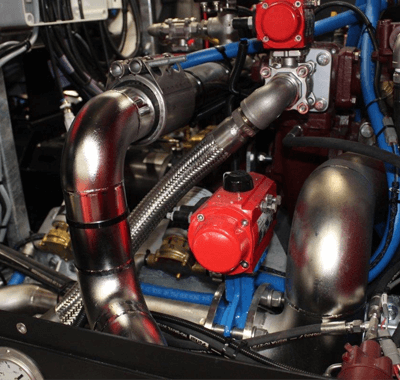

Onsite Service and Maintenance

Our Onsite Services In addition to our own facilities, International Corrosion Services also offer direct onsite services for our clients. This service allows us to treat stainless steel pieces, process plants or equipment which may be too large or immobile to transport for treatment. Our onsite team is highly experienced with specialised onsite expertise, including: […]

To pickle or not to pickle?

The difference between pickling and not pickling your stainless steel Our pickling and passivation bath is the largest and best of its kind in Australia. Our bath and process system ensure that all stainless steel is pickled and passivated in full compliance to the following standards: ASTM A380 ASTM A967 AS 1627.1 AS 1627.5 Our […]

Offshore Environment Maintenance

Stainless steel is a common element of oil and gas platforms and other offshore facilities. While stainless steel is used a number of ways for offshore facilities – including hydraulic lines and over a wide range of temperatures – improper maintenance can lead to corrosion, compromising its structural integrity. The most common signs of corrosion […]

Electropolishing and Hospitality

Electropolishing Electropolishing is a process that streamlines the microscopic surface of a metal object by removing metal from the object’s surface through an electrochemical process similar to, but the reverse of, electroplating. Electropolishing works by effectively removing stainless steel by first shedding the metal peaks, or high points, of the treated surface. There are numerous […]

Electropolishing and the Medical Industry

Electropolishing Electropolishing is a process that streamlines the microscopic surface of a metal object by removing metal from the object’s surface through an electrochemical process similar to, but the reverse of, electroplating. Electropolishing works by effectively removing stainless steel by first shedding the metal peaks, or high points, of the treated surface. There are numerous […]

Electropolishing and the Marine Industry

Stainless steel is a common choice for use in the marine industry due to its strength and structural integrity. 316 and 304 grade stainless steel are the most common types for marine use. While aluminum is sometimes used in marine construction, it does not offer the same corrosion resistance, strength or lustre that stainless steel […]

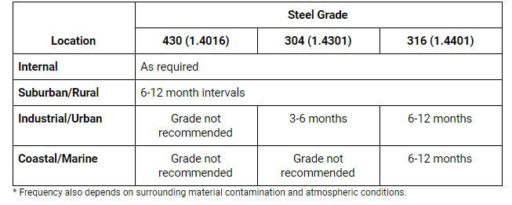

Ongoing Stainless Steel Maintenance and Cleaning

Stainless steel is an ideal material for many uses, including structures, industrial equipment and commercial plants. Steel is a common choice due to its strength, and stainless steel’s excellent corrosion and staining resistance is ideal for these applications all over the world. However, stainless steel can be susceptible to localised corrosion, or uniform corrosion if […]

Iron Contamination

Iron contamination occurs when there is a deposit of iron surface of stainless steel. Oxidation of the iron results in the accumulation of rust staining. This staining can be slight and only appear on the surface, or can cause severe pitting or marks. Common sources of iron contamination include: Stainless steel coming into contact with […]

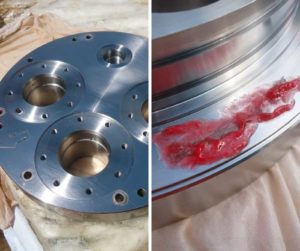

Good and Bad Electropolishing

Electropolishing Introduction Electropolishing streamlines the microscopic surface of a metal object. The process removes metal from the object’s surface through an electrochemical process which is similar to, but the reverse of, electroplating. Electropolishing effectively removing stainless steel by shedding the metal peaks or high points of the treated surface. The benefits of electropolishing are numerous, […]

Environmental, Health and Safety

Introduction The International Corrosion Services team take our environmental, health and safety commitments to both our staff and community very seriously. This includes preserving the environment and reducing our emissions footprint and ensuring our staff work safely with the dangerous chemicals required in the stainless steel industry. Our team is committed to not only working […]

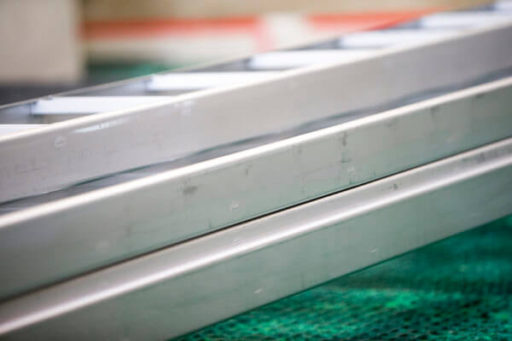

Electropolishing Vs Blasting

What Is Electropolishing? The Electropolishing process streamlines the microscopic surface of a metal object using an electrochemical process to remove metal from the object’s surface. This process is similar to, but the reverse of, electroplating. The process sheds the metal peaks (high points) of the treated surface. Our Electropolish Facilities International Corrosion Services’ electropolish bath […]

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023